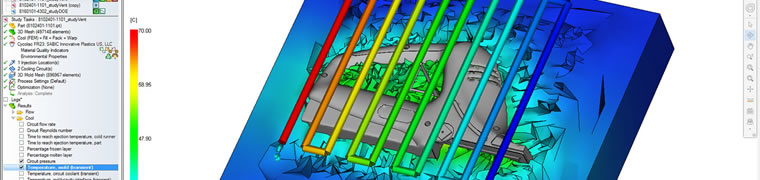

Firstly, customers provide us the data of product, such as ideas, models, samples, 2D or 3D drawings. We will translate the customer`s requirements into a 3D drawing or a rapid prototyping. If needed, we will use mold flow analysis to find out all the problems maybe occur, then optimize the mould structure before making the mould. Then we will start CNC and EDM processing, polishing, mould assemble and fitting to make the mould.

Client provide us datum ,such as(idea,model,samples,2D or 3D drawing),Useing CAD to translate client`s information into 3D drawing,to make fast molding products or make expeditious mould base on client`s requirement.Using expert evaluation systerm and CAE analyse to optimize mould structure ,and to design by three-dimension parts.After adopting CNC.EDM processing,cavity polishing ,we will produce by ourself or outer-assistant processing while the material inspection has proved eligible.